Add to Cart

Automotive chassis parts high anticorrosive performance electrophoretic paint

Product Introduction:

|

HLS-1701ELB/HLS-1701EG Black Cationic Epoxy Electrocoat for auto is a new generation electrophoretic coating researched and developed by HLS Paint (Shanghai) Co., Ltd.

|

|

It represents modern technology of cathodic electrophoretic coating that is environment-friendly with high property and low cost. Such coating does not contain heavy metal like lead, tin, cadmium and mercury etc. It is a two-component, water-dispersed resin,meanwhile, it took in features of previous products, and can adapt galvanized steel sheet perfectly, almost can be applied to foundation coating of all metal, such as: cold and hot rolled steel sheet, galvanized steel sheet, aluminum products, zinc-aluminum alloy sheet and stainless steel sheet etc.

|

This product features shown below:

①,Strong anti-corrosion properties, good salt spray resistance workpiece edge

②,The bath has strong anti-shrinkage and anti-pollution ability

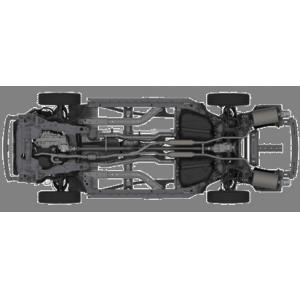

③,Ideal for high demand for salt spray industry, such as pipe trench, auto chassis parts, castings

The main component Matrix resin :

|

Pigment: carbon black, kaolin, antirust pigment

|

Solvent: alcohol ether |

|

Additives: surface active agent, prevent shrinkage cavity agent

|

|

|

Matrix resin: polyurethane modified epoxy resin

|

|

Product quality data :

| Project | Technical data | Test standard | ||

| Resin (HLS-1701ELB) |

Black Paste (HLS-1701EG) | |||

| pH | 25℃ | 6.0±1.0 | —— | GB/T 9724 |

| Conductivity | 25℃, μs/cm | 1400±600 | —— | HG/T 3334 |

| Appearance | —— | Milky white liquid | Black viscous liquid,no agglomeration | Visual |

| Storage stability | No stratified state, and there were no obvious difference compared to before storage |

In 5-35 ℃ temperature 6 months | ||

Note: pH, conductivity measurement in the resin/pure water = 1:1 dilution

Filling tank proportion and method:

⑴ Bath preparation

Ratio:

Resin 1200.00

Paste 200.00

DI water 2000.00

Total 3400.00

⑴ Ripening conditions

Sample quantity: 3000~5000g

Container: 5L (Diameter 16cm)

Tank temperature:28-30 ℃

Time: 24~48Hr

Mixed conditions: impeller diameter 8cm (speed 200rpm)

(3) Coating conditions

Experimental panel: phosphated cold-rolled steel plate

Tank temperature: 30-36℃

Pole ratio: A/C = 1/2 ~ 1/4

Distance of electrodes: 15cm

ED time: For full immersing 1-3 minutes ( 20 seconds soft start)

Baking conditions:(165-185)℃×(20-30)min (Keeping temperature of parts coated)

Construction equipment :

Cathodic electrophoretic coating construction in the electrophoresis tank, so need to have the following equipment:

Electrophoresis tank

Circulation devices (including filter, fill the paint device)

DI water equipment

DC power supply and the power supply unit

Anode box (tube) and circulation device

Ultrafiltration device

Cleaning devices

Heat exchanging equipment

Curing device

If you want to learn more about HLS coating products, please contact Sales Department of Shanghai HLS now